Lean project management strives to achieve operational excellence by optimizing efficiency and reducing waste in work processes.

Though the methodology has its origins in the auto industry, it has gained popularity in a wide range of industries. Let's talk about how it's used in digital project management.

What Is Lean Project Management?

Lean project management is a methodology focused on efficiency and waste reduction. Simply put: work smarter, not harder.

By emphasizing continuous improvement and customer value, lean aims to:

- Streamline processes

- Eliminate unnecessary steps

- Deliver higher quality outcomes with minimal resources

The lean approach traces its origins back to the early days of automobile manufacturing. Toyota took Ford Motor Company's famous streamlined mass-production strategy and adapted it to suit diverse product requirements and market demands. The Toyota Production System (TPS) was the precursor to lean project management.

Lean focuses on reducing three specific types of waste:

- Muda: Activities or processes that consume resources but don't add value that customers will pay for (also known as overproduction or overprocessing), such as testing and QA.

- Mura: Unevenness or inconsistency in workloads, such as task distribution that might cause some team members to be overloaded while others have insufficient work.

- Muri: Overburdened or unrealistic workloads, for example, assigning an unrealistic amount of work within an unreasonably tight deadline, which can increase the risk of worker burnout and errors.

Lean is one of the many agile project management approaches (others include Scrum and Kanban). Regardless of what agile methodology (or non-agile) you choose to follow, projects are always best managed in project management software.

5 Principles Of Lean Project Management

In "Lean Thinking," James P. Womack and Daniel T. Jones proposed five core principles for lean project management.

1. Identify the value

Simply put, this means identifying the things the customer is willing to pay for. This is not unlike presenting a project estimate and scope of work, along with proposed pricing to a client to determine if they want to move things forward.

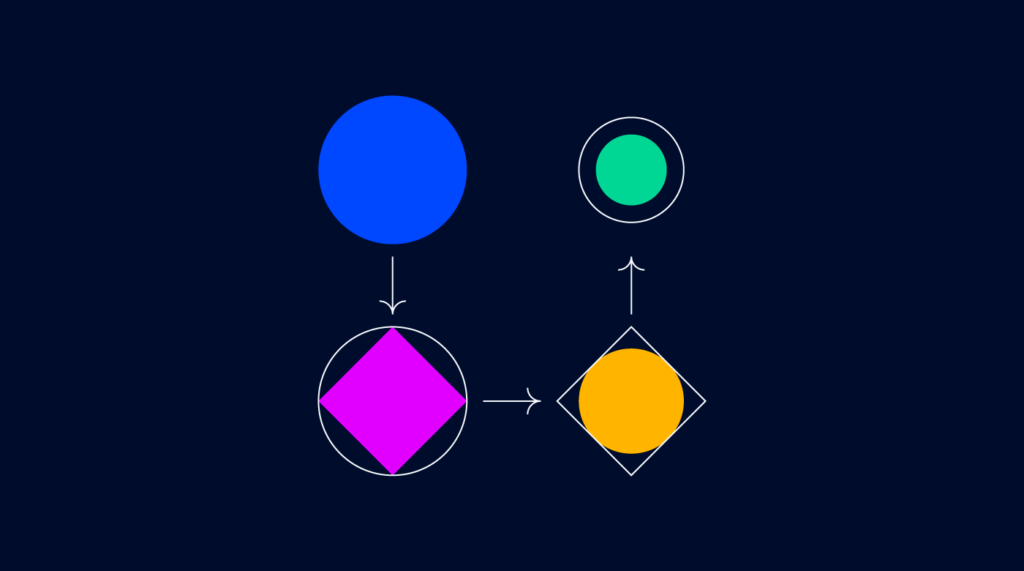

2. Identify the value stream for each product

Create a value stream map to get you a visual of all the work that needs to be done. This is essentially a flowchart that displays how materials and information move throughout the project process.

3. Create the flow

Establish a smooth and continuous flow of work with no downtime from the start of the project to the end. This is designed to create maximum efficiency in the process and help prevent lags or bottlenecks in production.

4. Establish the pull

Align your production with actual customer demand (i.e. a “pull” system), ensuring that resources are utilized efficiently based on real-time needs rather than pushing unnecessary work. This allows companies or project teams to avoid having to build up inventory or stockpile items in case of an order, saving the company time and money.

5. Pursue perfection

Strive for continuous improvement, eliminate waste and inefficiencies, and optimize your processes to achieve the highest level of efficiency and value delivery in your projects.

Lean Project Management Techniques

There are two key lean techniques to familiarize yourself with:

- Deming Cycle: This process involves continuous learning and adapting based on those learnings. It’s also referred to as the PDCA or PDSA cycle, which stands for Plan, Do, Check (or Study), and Act. Start by creating a plan to achieve a specific goal, then carry out that plan. Next you’ll check or study the impact of the plan, and then implement what you learned into your next plan.

- Lean Six Sigma: This project management process combines the Six Sigma method with the principles of lean. Six Sigma uses data, probabilities, and statistics to reduce waste and errors, as well as techniques like root cause analysis.

Benefits of Lean Project Management

The lean methodology has impacts that go beyond creating efficiencies. They include:

- Creating a culture of process improvement: Lean strives to keep working processes flexible so that all team members can make suggestions or try new ways of working. This can promote a mindset where teams are primed for uncovering ways to improve.

- Improving visibility with project stakeholders and customers: Lean projects require a lot of input from the customer or stakeholder to ensure no extra effort or scope is undertaken. When scoping deliverables, key stakeholders should be involved in the process to ensure the final statement of work only contains things that are of value.

- Reducing costs: Since the lean project management methodology prevents companies from building things before they’re needed (known as a just-in-time system), costs can be reduced by avoiding excess inventory. Additionally, by working to pursue perfection, lean thinking asks team members to be consistently keeping an eye on the bottom line.

Drawbacks of Lean Project Management

Like any project management methodology, lean can create some challenges.

- Losing track of the bigger picture: In a lean project life cycle, you’re looking for small and incremental improvements. Lean doesn’t provide many opportunities to take a step back and look at the bigger picture. In this type of environment, it’s possible to be “pennywise and pound foolish” because what may save lead time or effort in one part of the project may cause more work (or rework) in another.

- Being more reactive than proactive: Lean is designed to avoid overproduction. This can make predicting demand challenging when market trends and unexpected events change customer needs.

Lean Project Management Use Cases

Lean project management is most useful in project situations where:

- You have limited resources or budget: Lean will help you reduce waste and gain efficiencies, helping you make the most of your resources and cutting unnecessary costs or time sucks.

- You need space for flexibility and adaptability: Because lean moves quickly and involves regular reviews (often at set project milestones), teams can quickly pivot to address feedback, changes to the project plan, or new information or decisions affecting the project.

- You have a tight deadline: Lean emphasizes quick responses to change, allowing the team to adapt to changes that might otherwise throw a wrench in their attempts to get done work by the deadline.

- You need to prioritize continuous improvement: Lean provides a built-in system for improving over time. This is ideal for teams made up of junior members or teams that are new to working together.

What's Next?

Lean is one of many topics of discussion in our DPM membership community—sign up and get access to all the conversations in Slack, as well as 100+ templates, examples, and samples for common project documentation.